Phone

Follow us on

Firmitas Inspectra / IT Services

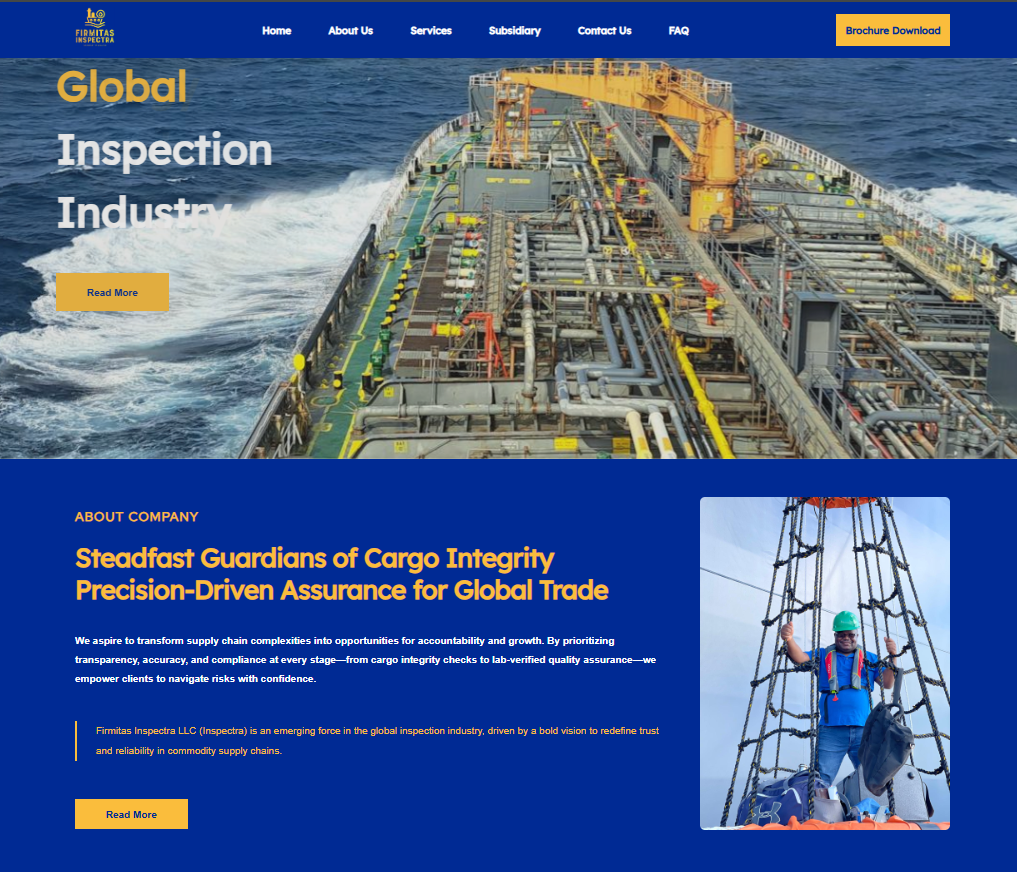

Oil, Gas, Commodities Inspection Experts

Firmitas Inspectra LLC (Inspectra) is an emerging force in the global inspection and quality assurance sector, offering a comprehensive suite of services including oil and gas inspections, vessel surveys, testing, stock monitoring, and third-party superintendency. Trusted by clients across the commodity supply chain, Inspectra delivers precision, transparency, and unmatched integrity.

Brief

Firmitas Inspectra was founded with a bold ambition: to reshape the way the world perceives inspection services. In an industry where reliability and trust are paramount, Inspectra sets new standards by combining rigorous methodologies with modern technologies. Recognizing the growing demand for on-demand inspection solutions, Inspectra set out to develop an intuitive digital platform to streamline service requests and reporting.

Goal

With a vision to expand their reach across international markets, the leadership team at Inspectra, led by forward-thinking executives, aims to establish a solid digital presence. Eschewing traditional advertising in favor of long-term, value-driven growth, Inspectra partnered with leading digital experts to build a user-centric web application. The goal: empower clients to effortlessly schedule inspections, access test reports, and monitor supply chain integrity—anytime, anywhere.

Our Plan & Process

To achieve Inspectra’s vision, we implemented the following:

01

Planning

Our strategy team collaborated with Firmitas Inspectra LLC to deeply understand their inspection workflow, compliance standards, and technical requirements. Based on this discovery, we created user journey flows, wireframes, and service architecture tailored for the commodity inspection domain—laying the foundation for a scalable digital ecosystem.

02

Execution

Our UI/UX designers crafted clean, intuitive interfaces in Figma, designed to serve both enterprise clients and inspection teams in the field. Meanwhile, the development team implemented the platform using cutting-edge technologies, ensuring smooth navigation and data security. Rigorous QA testing across multiple devices guaranteed a seamless experience in real-world usage conditions.

03

Output

The resulting web application empowers clients to schedule inspections, track reports, monitor stock levels, and receive testing certifications in real time. Integration with GPS and logistics APIs allows for live vessel monitoring and remote coordination. The platform supports global operations, helping Inspectra reinforce trust and transparency in every step of the supply chain.

How We Delivered Results

1. Completed Rapid Inspection

We conducted a full inspection within 72 hours, meeting the client’s urgent operational deadlines.

2. Identified Critical Safety Issues

Twelve major safety concerns were detected and reported for immediate corrective action.

3. Reduced Operational Downtime

Our findings and recommendations led to a 30% decrease in equipment downtime.

4. Achieved ISO Compliance

The inspection ensured full compliance with international ISO safety standards.

5. Client Satisfaction

“The team was prompt, professional, and exceeded our expectations.”

1. Implement Quarterly Inspections

Regular inspections will help catch issues early and maintain consistent safety standards.

2. Introduce Digital Logging System

A digital platform can improve inspection record-keeping, traceability, and reporting efficiency.

3. Explore AI-Powered Quality Control

Adopting AI tools can enhance real-time monitoring and predictive maintenance accuracy.

4. Enhance Staff Training

Conduct regular workshops to ensure inspection staff stay updated on industry standards.

5. Expand Scope for Preventive Maintenance

Include broader asset checks to minimize unexpected failures and improve long-term reliability.

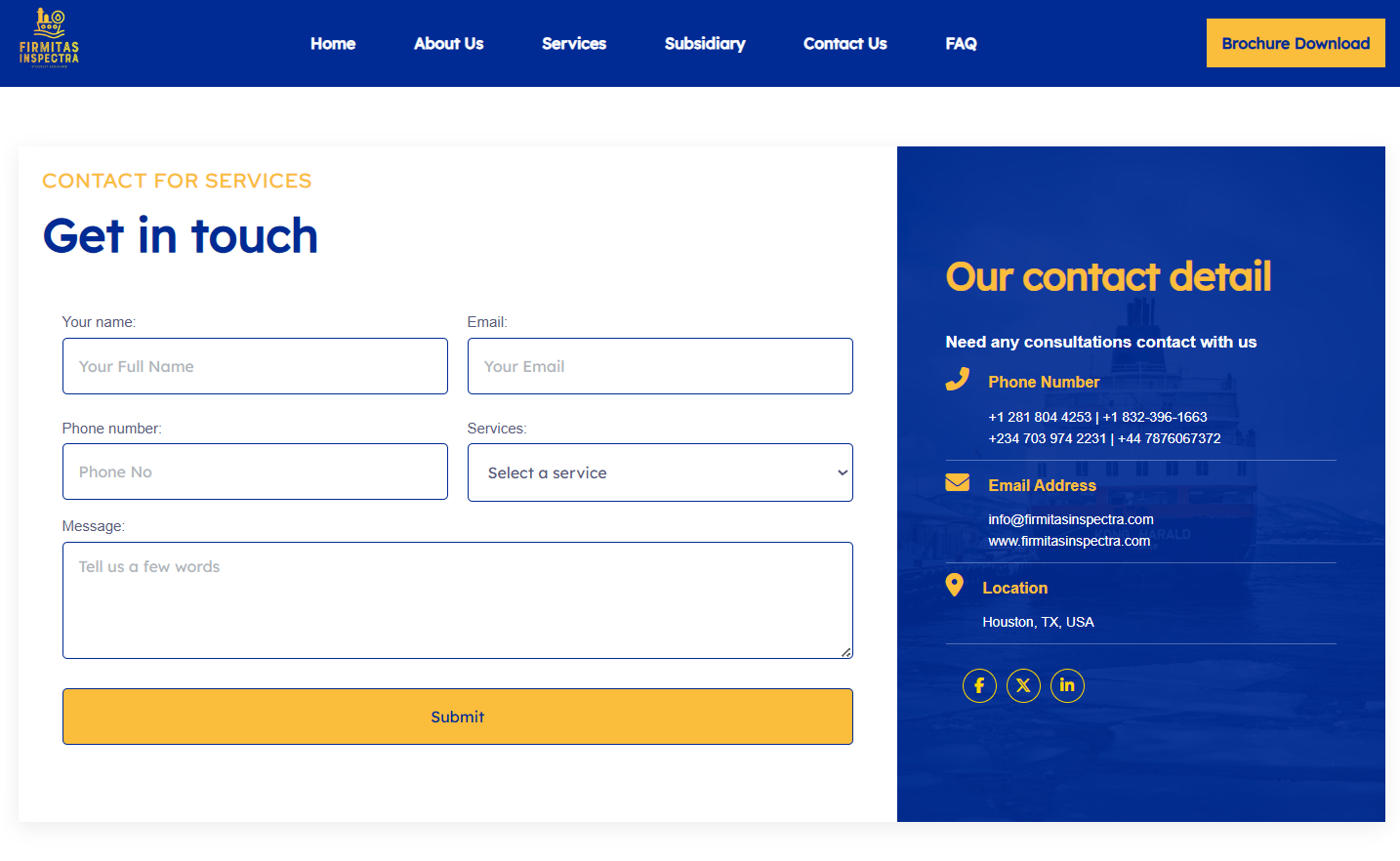

High Fidelity Wireframes